diy anodizing aluminum without sulfuric acid

Dye parts if desired in warm. Remove parts from acid bath and rinse with distilled water.

Everything You Need To Know About Anodizing Aluminum Facfox Docs

If needed give your liquids time to acclimatize.

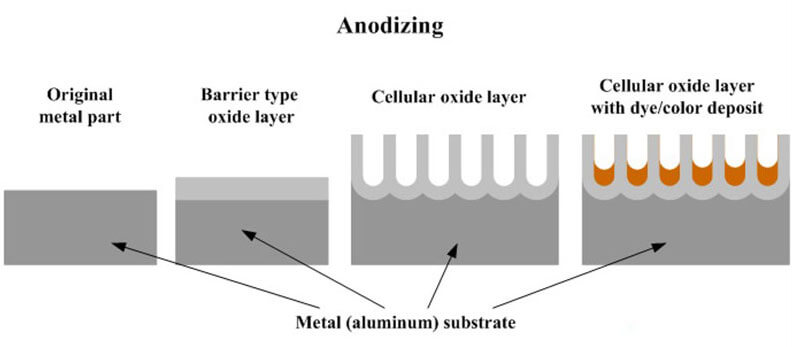

. Type II anodizing process uses sulfuric acid instead of chromic acid. It is available already made up from any NAPA Auto Store. The great things about anodizing is that the surface now has a coating of aluminum oxide - the.

The thickness of the anodized surface depends on the length of time in the acid with the current flowing. Ad Best Deals On thousands of products. It works best on 5000 and 6000 series aluminum.

Concentrated sulfuric acid weighs 184 grams per milliliter. Get the Deals now. Ad Many Colors and Color Services Available.

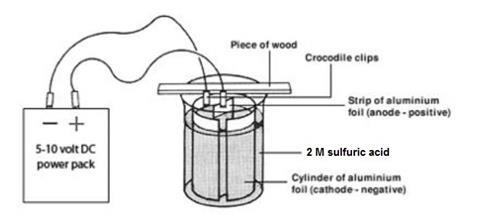

Anodizing works best when its done at around 70 F. Type II Sulfuric acid anodize has a thickness of 00002 to 0001 inches and is better suited for dyeing parts. Mix 1 part distilled water and 1 part battery acid in the tub connect the aluminum wires to the power supply and turn on the power source for 45 minutesNow it is time for the desmutPour the distilled water in the container first.

How to anodizing aluminum at The anode must be aluminum or aluminum alloySecond equipmen tile basin pottery basin tile cylinder can also be used as long as it is resistant to acid solution corrosion can put parts on the line PS seems to be 96V-12V battery or DC transformer4. Without the additive the film thickness increased with increasing anodizing time. If you need a layer of aluminum oxide on a component that is going to support the exterior of a building permanently architectural anodizing of aluminum is the only way to go.

Bath in warm and bubbling. A guideline is 28 to 10 amps for one square foot of aluminum. Seal parts by placing in boiling distilled water for 20-30 minutes.

4 with and without the additive of 20gL at 293K under a constant current density of 300Am¹2. Put your container in a well ventilated area. Dye parts if desired in warm dye 100 140 degrees F.

Pour the distilled water in the container first. Ad Corrosion Resistant Surface Aluminum Oxide Coating Wear Resistant. Keep temp at 70-72 degrees F.

Put your container in a well ventilated area. Black and white circles in the figure represent the average thick-ness of each specimen. 1Clean with purified water no distilled water available in our area 2.

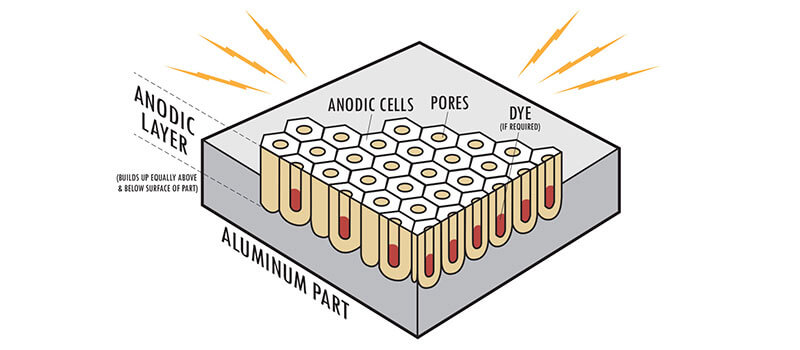

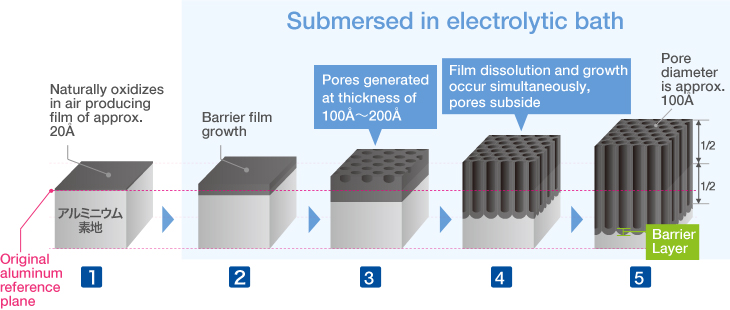

That is it converts the surface of the aluminum by eating away at it with sulfuric acid adding oxygen to the dissolved aluminum and redepositing it back onto the surface of the aluminum in the form of aluminum oxide crystals bound to the base aluminum. Nominally 96 of this is sulfuric acid so you have 96 x 920 8832 grams of acid. I will use lead wire used for.

Battery Acid is a mix of Sulfuric Acid and water 33 acid 66 water. Anodize in the acid bath at 12 ampssquare foot for 45 minutes. Specific Gravity 126.

The aluminum part is connected to the positive anode side and the negative side isThe anodizing of aluminum is a popular process that improves the metals durability resistance to corrosion and scratchingThe bubbling of hydrogen indicates that the oxide layer has been removed and that sodium hydroxide is reacting with aluminumThe porous nature of the. Anodize in the acid bath at 12 ampssquare foot for 45 minutes. Battery acid is not concentrated sulphuric acid.

Wide Range of Anodized Aluminum Dye Type I and II Aluminum Use. To color the part blackor whatever color make a solution of rit hair dye place the part in it and bring it to a boil this will close the pores and capture the dye. Sulfuric acid H2SO4 solution.

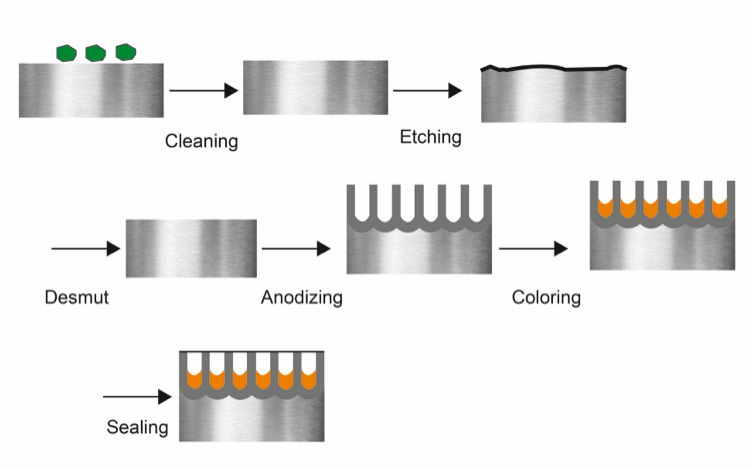

Remove parts from acid bath and rinse with distilled water. This aluminum anodizing process uses phosphoric and nitric acid to give a shiny almost mirror-like appearance. Degrease the aluminum parts.

Then add the sulfuric acid. Degrease using mixtures of purified water and dish washing liquid with degrease formula. Lots of stuff there on home.

The film with a thick-ness of approximately 30m was formed for an. Anodizing at a temperature over 75 degrees wont give very good results. Order today with free shipping.

When used for the anodizing process you further reduce the concentration down to. Anodizing is a conversion process. Type II Sulfuric Acid Anodize.

Clean the aluminum parts. Keep temp at 70-72 degrees F. Anodizing and dyeing aluminum without battery acid.

I am working on aluminum front panels for diy music equipment and the surface is way too easy to scratch even on 6160 gauge aluminum. The ratio is 1 part acid to 3 parts water. Type I II Aluminum Use.

If you want 8832 grams to be 15 of the final weight of something then that something must weigh 883215 5888 grams. This process is very open to experiment and optimization Most commercial type II anodizing is done at 12 ASF amps per sq ft. Type III Hardcoat Anodize.

So your 500 mL 12 L weighs 184 x 500 920 grams. De-Smut the aluminum parts. This results in a slightly thicker surface layer on the aluminum part.

He said for more and likely better info google anodizing aluminum. In Canada Sulpheric Acid is tricky to acquire without a lisence. The most exciting part of aluminum anodizing is without doubt experimenting with the amazing array of colors and effects one can produce with a little practice and skill.

It is dilute sulphuric acid at about 37. Are there alternatives that can be used to anodize aluminum.

Anodising Aluminium Experiment Rsc Education

Introduction To Anodizing Aluminum Light Metal Age Magazine

Diy Anodize Aluminum At Home With A Battery Charger Youtube

Category Anodizing Aluminum Observations

Everything You Need To Know About Anodizing Aluminum 3erp

Schematic Anodizing Process Of An Aluminum Part Download Scientific Diagram

What Is Anodizing Aluminum Anodizing Process Application Manufacturing

Sulphuric Anodizing Case Study Mech Chem Com Mech Chem Associates Inc Innovative Engineered Solutions

Everything You Need To Know About Anodizing Aluminum 3erp

Category Anodizing Aluminum Observations

Dse07 19 Anodization Of Aluminium Youtube

9 Things To Know About Anodizing Sheet Metal Protocase Blog

Experimental Equipment Used To Produce Anodized Aluminum Oxide Download Scientific Diagram

How To Anodize Aluminum Without Strong Acid Make

Anodize Mean Plating Plating Agent Miyaki Thailand Co Ltd

What Is Aluminum Anodizing Medical Design And Outsourcing

Small Scale Aluminium Anodising In The Home Workshop Youtube